What Is a Milanese Buttonhole?

If you’re more familiar with pork Milanese that a Milanese buttonhole, don’t sweat it. There’s a reason why the Milanese buttonhole isn’t exactly a household name: it’s a one-inch detail that cannot be added by machine but requires painstaking handwork to create, and has traditionally been reserved for high-end bespoke suits.

It’s subtle enough that it may not stand out from an ordinary buttonhole at first. But once you’ve seen the difference, you’ll never be able un-see it again.

How Is a Milanese Buttonhole Made?

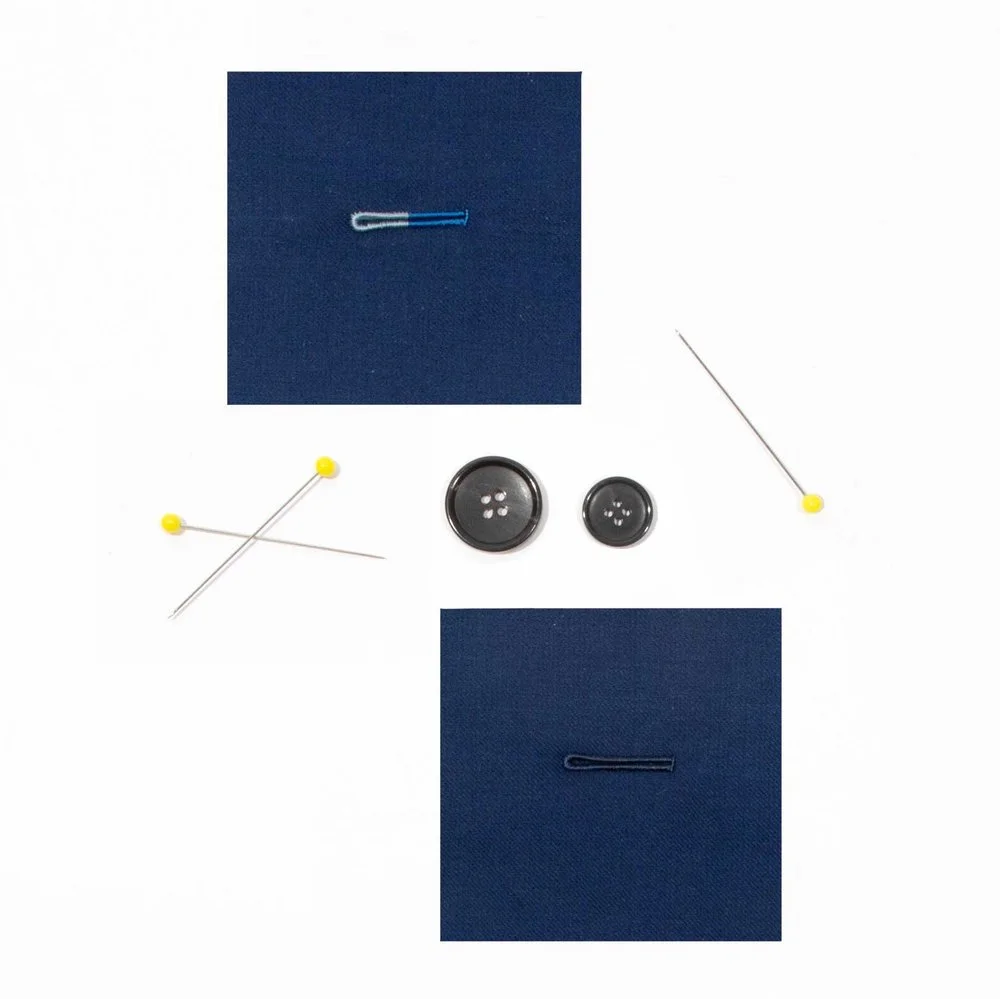

A Milanese buttonhole is located on the lapel of a suit jacket, where a boutonniere would traditionally be placed (for this reason, it’s also sometimes called a Milanese boutonniere). To create a Milanese buttonhole, a tailor must first cut a slim hole into the fabric, and then bind it with a taut silk cord known as a “gimp” by threading it with silk thread. In simpler terms, this means that the hole cut into the lapel must be closed by a tight, calculated series of weaves tied with thread, done carefully to avoid any imperfections and pulled so tightly that the buttonhole almost “shines.”

If you think this sounds difficult, it’s because it is. It typically takes a tailor one hour to create a single Milanese buttonhole.

What Is a Milanese Buttonhole For?

Unlike the buttonholes that close the front of your suit jacket, a Milanese buttonhole doesn’t have a strictly practical purpose—and that’s just part of the fun. A Milanese buttonhole is a classic signifier of quality, one that will be enjoyed by yourself (and the well-trained eye of a stranger) every time you slip the jacket on.